| Physical property | Properties | A2 + PVC |

| Fabric | Polyester

1000D (20 x 20 / inch²) |

|

| Total Weight

KS K 0514 : 1991 |

640 g/m2 | |

| Braking Strength

KS K 0520:2004, C.R.E |

warp 2100N

weft 1990N |

|

| Tear Strength

KS K 0536:2004, C.R.E, |

warp 420N

weft 240N |

|

| Adhesion

KS K 0533:2005, C.R.E |

95N/5cm | |

| Cold Resistance | -40±1℃ , 30분

No problem |

|

| Flame Retardancy

KS K 0580:2001 |

Resist printing class 1 | |

| Surface Treatment | external acrylic coating | |

| The Others | U/V |

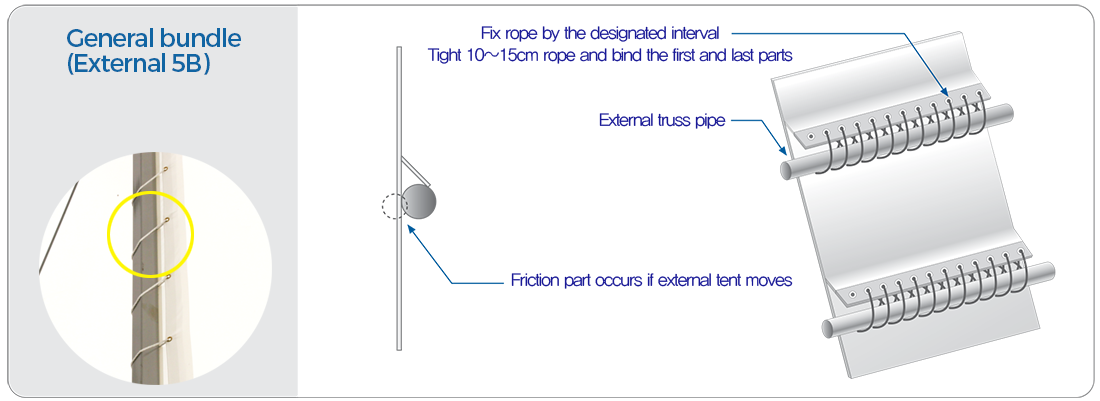

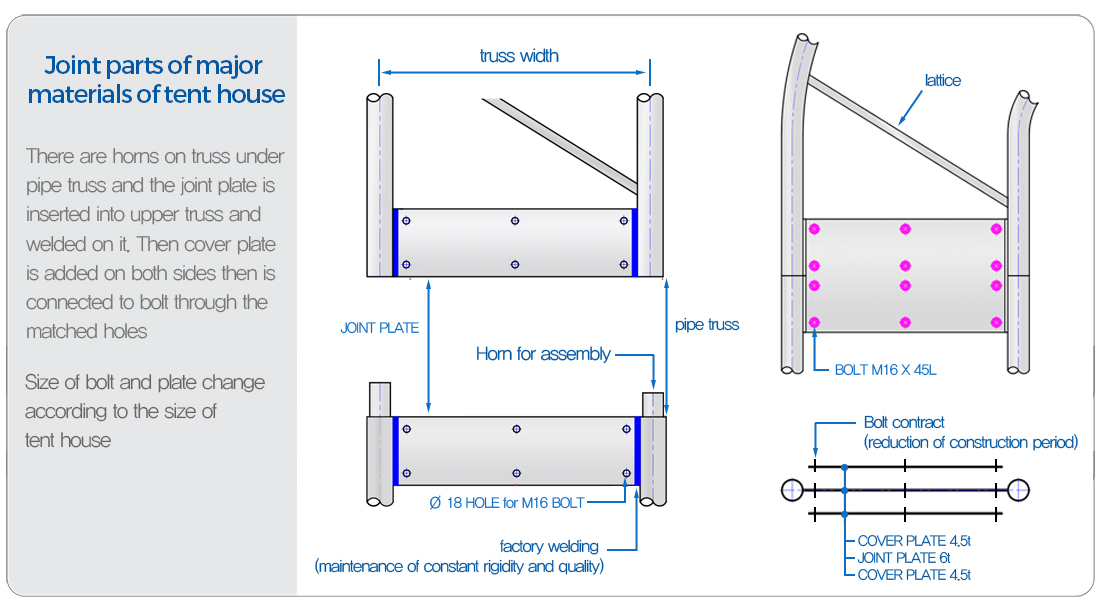

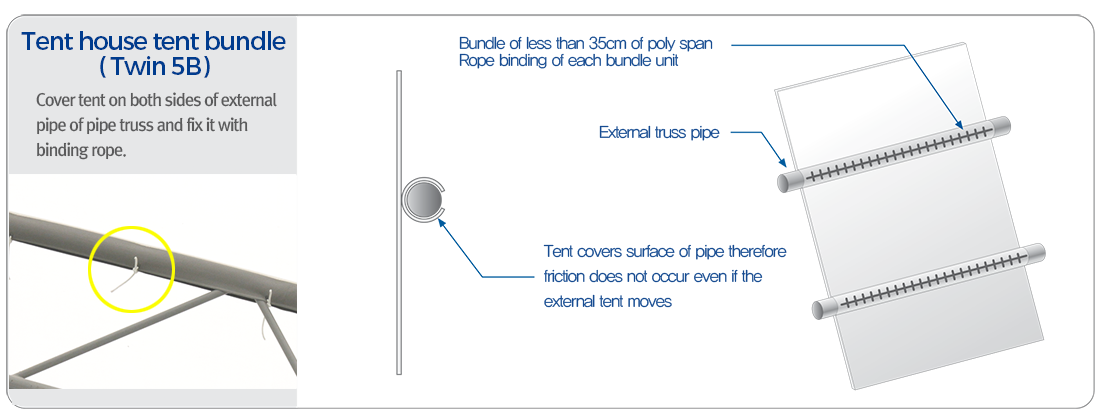

| construction | 1) Main structure is installed by 2m and there is no structure part contact with exterior tent within main interval of 2m. Therefore, it has design in which friction between exterior tent and structure is minimized and endures load of 30m/s of wind speed and 60Kg/㎡ of snow cover.

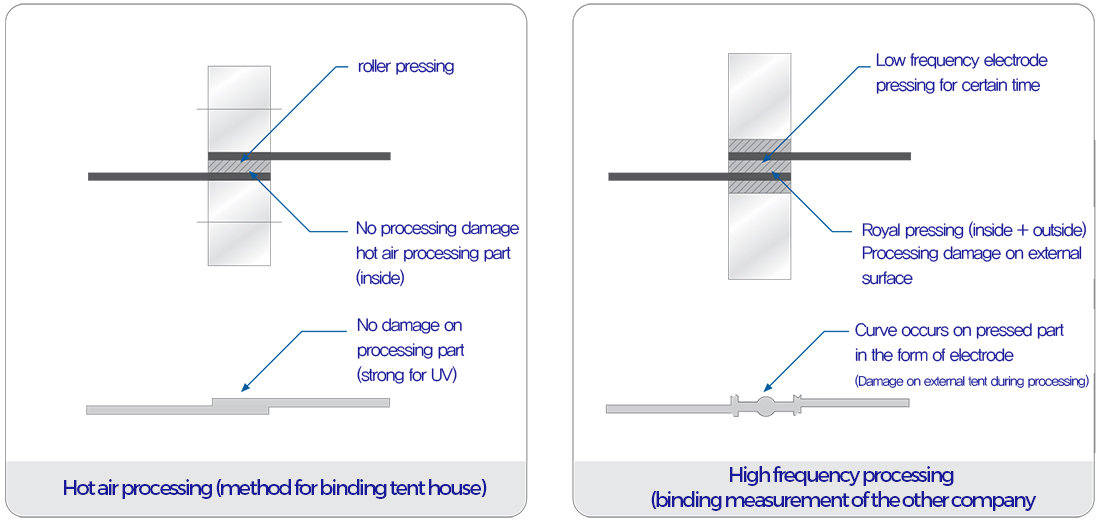

2)No damage caused by friction between external tent and steel structure on external tent(Improvement of stripping time of external tent through bonding construction method over original lifespan of external tent) ?* See cahpter 2 twin 5B construction method 4)Minimization of damage on processed area through hot air processing binding process of external tent and binding part (strong for UV) * See chapter 3 hot air processing |

[Self-assembly tent house Patent No. 0235289] Steel structure part

[Design proposal No. 0176698] Tent for tent house-construction part of external tent

[Design proposal No. 0344228] Tent for tent house-processing part of external tent

Quality assurance of external tent : 5 years

A lot of investment costs are required but the product is beneficial taking into account usage period, safety and follow-up maangement.

주원엔지니어링의 묶음방식